Clause 3 – How to understand the definition of “basic insulation”

basic insulation: insulation applied to live parts to provide basic protection against electric shock

Generally speaking, a layer of insulation that is in direct contact with a live part can be a common insulating material (such as plastic materials such as PVC and ABS), or it can be air or a distance ( creepage distance) formed on the surface of the insulating material. Most countries do not accept structures where users can touch basic insulation. Therefore, basic insulation is generally located inside the appliance and cannot be touched during normal operation.

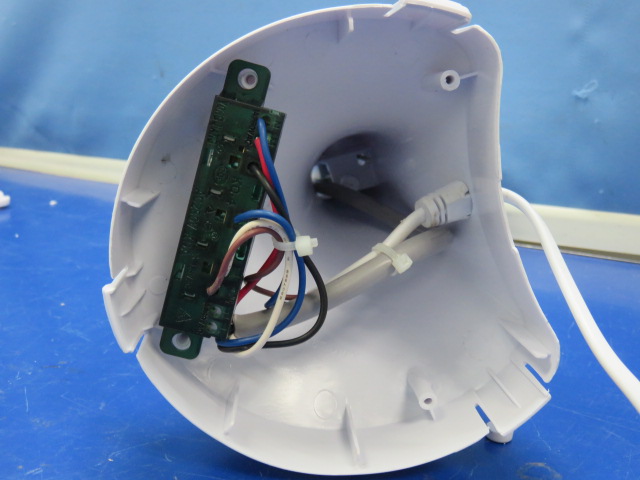

As shown in the left picture below, it is a photo of the bottom cover of a fan, and the right picture is a photo without the bottom cover. The blue and brown wire skin inside the supply cord in the right picture can be considered as basic insulation. At the same time, the white, red and black wire skins on the switch connected to the black shell can also be judged as basic insulation; the live parts here are the copper core in the wire. In addition, the distance between metal conductor in the switch and the inner surface of the white shell can be judged as basic insulation. From the perspective of creepage distance, the electricity in the conductor inside the switch is conducted (climbed) along the insulating surface of the switch to the inner surface of the white shell (the left small corner of the right picture), and this distance can be considered as the creepage distance of basic insulation. From the perspective of electrical clearance, the electricity in the conductor inside the switch is directly conducted through the air between the inner surface of the fan bottom cover and the switch shell, and this distance between the air is judged as the clearance of basic insulation. (The white plastic shell is judged as additional insulation)

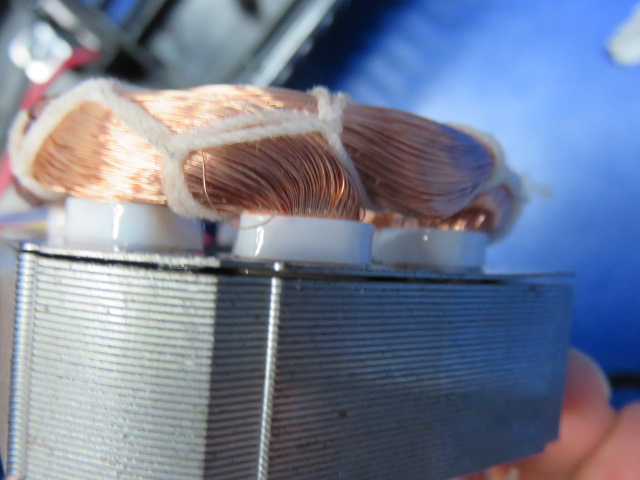

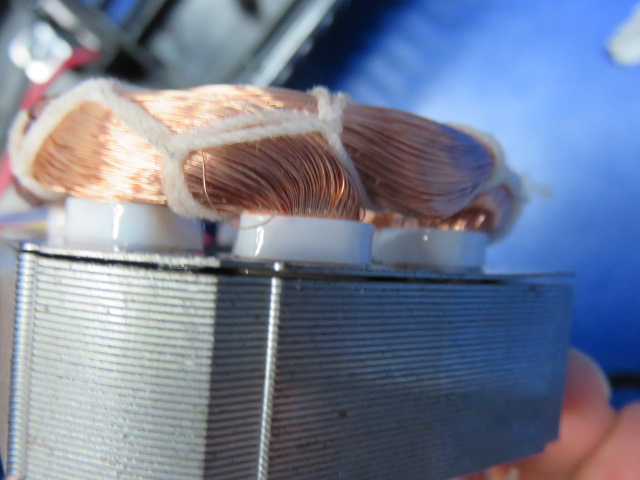

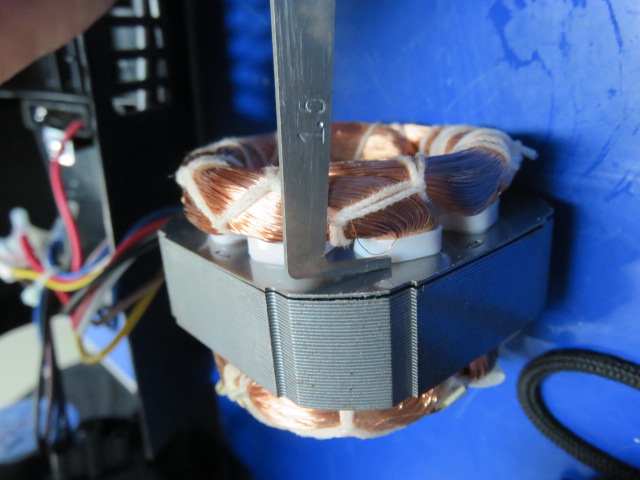

As shown in the figure below, the lacquered conductors of windings of the motor is fixed by the white slot paper inserted into the motor stator. The winding is identified as an exposed live part by the standard. The lacquered conductors of windings and the motor stator form a conductive loop through the slot paper (generally speaking, if it is a class I appliance, the stator connected to the motor housing will also be grounded because the motor housing is grounded. If it is a class II appliance, the motor housing and the motor stator are an ungrounded intermediate metal component). Although the conductivity of the slot paper is not enough, a weak current will still be produced on the slot paper. The amount of current generated here is directly related to the performance of the slot paper. The slot paper material here can be determined as basic insulation. The surface of the slot paper can be connected to the metal laminations of the winding, so the distance on the slot paper surface can be determined as the creepage distance of basic insulation; the material of the slot paper itself plays the role of solid insulation (although there is no thickness requirement for solid insulation, it still needs to meet the leakage current and electrical strength requirements of Chapters 13 and 16); accordingly, the electrical clearance in the above figure is the shortest distance between the winding and the stator laminations in the air.

As shown in the figure below, the motor winding wire is not fixed properly and is very close to the motor stator. It can no longer meet the creepage distance and clearance distance requirements of clause 29. This is a common non-compliance item.

As shown in the animated image below, the red arrowhead line marks the location of the basic insulation, including clearance and creepage distance path. The windings in the reactor used in air conditioners are live parts, and the windings are separated from the stator core by bobbin, which forms the basic insulation.

Basic insulation of fan motor