Clause 3 – How to understand the definition of “safety extra-low voltage”

safety extra-low voltage: voltage not exceeding 42 V between conductors and between conductors and earth, the no-load voltage not exceeding 50 V When safety extra-low voltage is obtained from the supply mains, it is to be through a safety isolating transformer or a convertor with separate windings, the insulation of which complies with double insulation or reinforced insulation requirements.

NOTE 1 The voltage limits specified are based on the assumption that the safety isolating transformer is supplied at its rated voltage.

NOTE 2 Safety extra-low voltage is also known as SELV.

From the name – safety extra-low voltage, this definition has the word “safety” more than extra-low voltage. However, in this standard, we have explained before that the concept of safety is a relative concept, which has been explained in Foreword-1. At the same time, the “safety” defined in this clause does not mean absolute safety so that SELV can be directly touched by users. Only SELV circuits that meet the requirements of Section 8.1.4 can be touched by users. This voltage is generally obtained by stepping down the voltage through a safety isolating transformer or a converter with a separate winding. Usually, it is obtained through a safety isolating transformer. The safety isolating transformer or converter with a separate winding here can ensure that the primary winding and the secondary winding are physically separated in structure, that is, the primary and secondary windings will not be in direct contact; a common example of the voltage regulation method corresponding to this circuit separation by separate windings is the RC step-down method, which is to connect a resistor and a capacitor in parallel in series to the 220V circuit. In the RC step-down method, the high-voltage part and the low-voltage part are connected in the circuit. Obviously, the former method of separating the circuit by physical means is safer. If it is just a simple physical separation, it still cannot meet the safety requirements. The isolating required by the standard needs to meet the requirements of double insulation or reinforced insulation. Simply put, if there is a very simple insulation between the high-voltage part and the low-voltage part – such as a thin plastic sheet with low temperature resistance, this insulation is easy to fail under high temperature or high voltage conditions and basically cannot play an insulating role, although this layer of plastic sheet also physically separates the high-voltage and low-voltage circuits. The isolating requirements of double insulation and reinforced insulation are also a means of double protection.

Here, we need to add that SELV has regulations on voltage values. The voltage specified here is the effective value of the voltage. Usually, the peak value of the voltage is higher than the effective value, and the voltage limit specified in clause 8.1.4 is the requirement for the peak value. We will explain its test requirements in detail in clause 8.1.4. Note 2 of first paragraph in Clause 3 give sentence “NOTE 2 When the terms “voltage” and “current” are used, they are r.m.s. values, unless otherwise specified.”

As shown in the figure below, the transformer has three plastic brackets placed vertically into the disc to separate the primary and secondary windings (the primary and secondary windings are wrapped with blue plastic tape on the outside), and the primary and secondary windings are physically isolated.

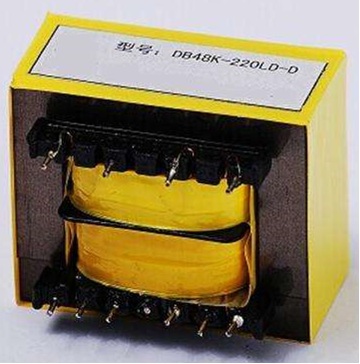

As shown in the figure below, the transformer has yellow tape wrapped around the primary and secondary windings in the middle. We need to pay special attention to the creepage distance of the black bracket between the two windings to see if it can meet the creepage distance requirements for reinforced insulation. If not, the transformer cannot be judged as a safety isolating transformer.

We will explain the structure of the safety isolating transformer in detail in the next post.