Clause 3 – How to understand the definition of “reinforced insulation”

reinforced insulation: single insulation applied to live parts, that provides a degree of protection against electric shock equivalent to double insulation under the conditions specified in this standard.

NOTE It is not implied that the insulation is one homogeneous piece. The insulation may comprise several layers which cannot be tested singly as supplementary insulation or basic insulation.

From the notes, supplementary and basic insulation can be tested one by one, which means that supplementary and basic insulation can be easily distinguished and separated. Correspondingly, if an insulation consists of multiple layers or multiple insulations that are not easy to separate and distinguish, but it is equivalent to double insulation in actual insulation effect, it can be defined as reinforced insulation; in addition, if it is only one layer or a single dielectric insulation, its insulation effect is equivalent to double insulation, it can also be defined as reinforced insulation.

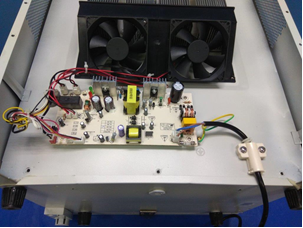

As shown in the two pictures below, the left picture is a photo of the back of a refrigerator. The circuit board inside can be seen through the metal grille in the left picture, and the internal photo is the right picture. There are live parts on the PCB, and the user can touch the grille. The air between the gap of the grille and the live parts on the circuit board can form a conductive loop. Therefore, this distance can be determined as an clearance with reinforced insulation. Because the clearance is composed of an air loop, the air loop cannot be separated, and we don’t even know where to divide this air into several parts. Here, two points need to be noted. If the metal grille is not grounded, the air between the grille and the live parts in the circuit board needs to meet the requirements of reinforced insulation (according to the requirements of clause 8.2 for class II appliance), if the metal grille is grounded, then the air between the grille and the live parts in the circuit board only needs to meet the requirements of basic insulation, because basic insulation plus earthing is a class I appliance with double protection measures, and the user can touch the earthing metal parts.

The submersible pump shown below has a shaded pole motor inside, with the windings wrapped in yellow insulation. To prevent water damage, the entire motor stator is wrapped in epoxy resin. After the windings are wrapped, it is not possible to effectively test the basic insulation and supplementary insulation. Before the epoxy resin is poured, the yellow insulation can be considered basic insulation and the epoxy resin can be considered supplementary insulation. However, when the epoxy resin is poured into the pump housing, it will adhere to the yellow insulation material very tightly, and the two materials cannot be separated for evaluation, such as evaluating electrical strength tests. Therefore, reinforced insulation is formed from the pump winding to the externally accessible epoxy resin surface.