Isigaba sesi-3 – Iqondwa kanjani incazelo ye-“reinforced insulation”

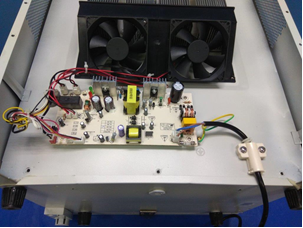

Njengoba kukhonjisiwe ezithombeni ezimbili ezingezansi, isithombe esingakwesokunxele yisithombe sangemuva sesiqandisi. Ibhodi lesifunda ngaphakathi lingabonakala nge-grille yensimbi esithombeni kwesokunxele, futhi isithombe sangaphakathi isithombe esifanele. Kunezingxenye ezibukhoma ku-PCB, futhi umsebenzisi angakwazi ukuthinta i-grille. Umoya ophakathi kwegebe le-grille kanye nezingxenye ezibukhoma ebhodini lesifunda ungakha i-loop conductive. Ngakho-ke, leli banga linganqunywa njengemvume ene-insulation eqinisiwe. Ngoba imvume kanye nbsp; futhi i-nbsp;yakhiwe nge-air loop, iluphu yomoya ayikwazi ukuhlukaniswa, futhi asazi nokuthi singawuhlukanisa kuphi lo moya ube izingxenye ezimbalwa. Lapha, amaphuzu amabili adinga ukuqashelwa. Uma i-grille yensimbi ingagxiliwe, umoya ophakathi kwe-grille nezingxenye ezibukhoma ebhodini lesifunda udinga ukuhlangabezana nezidingo zokufakwa okuqinisiwe (ngokwezimfuneko zesigatshana 8.2 somshini we-class II), uma i-grille yensimbi iphansi, khona-ke umoya ophakathi kwe-grille nezingxenye ezibukhoma ebhodini lesekethe udinga kuphela ukuhlangabezana nezimfuneko zokugqumisa okuyisisekelo, ngenxa yokuthi ukufakwa kwensimbi okuyisisekelo kanye nokufakwa komhlaba kuwumshini weSigaba I onezinyathelo zokuvikela ezikabili, futhi umsebenzisi angakwazi ukuthinta izingxenye zensimbi.

Iphampu engaphansi kwamanzi eboniswe ngezansi ine-pole motor efakwe umthunzi ngaphakathi, namawindi asongwe ngendlela ephuzi. Ukuvimbela ukulimala kwamanzi, yonke i-motor stator isongwe nge-epoxy resin. Ngemuva kokuthi ama-windings ehlanganiswe, akunakwenzeka ukuhlola ngokuphumelelayo ukufakwa okuyisisekelo kanye nokufakwa okungeziwe. Ngaphambi kokuba kuthelwe i-epoxy resin, ukufakwa okuphuzi kungabhekwa njenge-insulation eyisisekelo futhi i-epoxy resin ingabhekwa njenge-supplemental insulation. Kodwa-ke, lapho i-epoxy resin ithululelwa endlini yephampu, izobambelela ngokuqinile ezintweni eziphuzi zokuvikela, futhi izinto ezimbili azikwazi ukuhlukaniswa ukuze zihlolwe, njengokuhlola izivivinyo zamandla kagesi. Ngakho-ke, ukwahlukanisa okuqinisiwe kwakhiwa kusuka empompini ejikajikayo ukuya endaweni efinyeleleka ngaphandle ye-epoxy resin.

As shown in the two pictures below, the left picture is a photo of the back of a refrigerator. The circuit board inside can be seen through the metal grille in the left picture, and the internal photo is the right picture. There are live parts on the PCB, and the user can touch the grille. The air between the gap of the grille and the live parts on the circuit board can form a conductive loop. Therefore, this distance can be determined as an clearance with reinforced insulation. Because the clearance is composed of an air loop, the air loop cannot be separated, and we don’t even know where to divide this air into several parts. Here, two points need to be noted. If the metal grille is not grounded, the air between the grille and the live parts in the circuit board needs to meet the requirements of reinforced insulation (according to the requirements of clause 8.2 for class II appliance), if the metal grille is grounded, then the air between the grille and the live parts in the circuit board only needs to meet the requirements of basic insulation, because basic insulation plus earthing is a class I appliance with double protection measures, and the user can touch the earthing metal parts.

The submersible pump shown below has a shaded pole motor inside, with the windings wrapped in yellow insulation. To prevent water damage, the entire motor stator is wrapped in epoxy resin. After the windings are wrapped, it is not possible to effectively test the basic insulation and supplementary insulation. Before the epoxy resin is poured, the yellow insulation can be considered basic insulation and the epoxy resin can be considered supplementary insulation. However, when the epoxy resin is poured into the pump housing, it will adhere to the yellow insulation material very tightly, and the two materials cannot be separated for evaluation, such as evaluating electrical strength tests. Therefore, reinforced insulation is formed from the pump winding to the externally accessible epoxy resin surface.